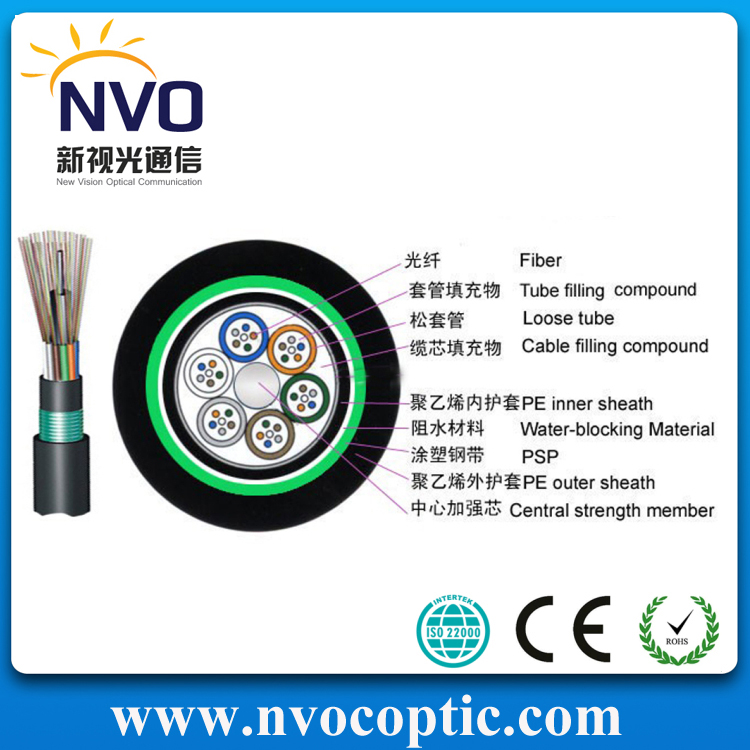

GYTA53+33Submarine Steel Wire Armored Fiber Cable

Type and specification: GYTA53+33

Structure describing:GYTA53+33 The structure of the cable is 250 (including m optical fiber set into the pine casing of high modulus materials, filling waterproofing compound pine casing. The center is a metal cable core; strengthen the core for some of the optical cable, metal outside still need to strengthen the core crowded on a layer of polyethylene (PE). Pine casing (and filling line) around the center to strengthen the core of twisted into a compact and circular cable core, core within the gap to block water filling filler. Plastic coated aluminum belt (APL) is applied to longitudinally wrap crowded on a layer of PE sheathed inside, after several thin single-layer garden after the spiral twisted steel wire armored HDPE cable outer sheath.

1.Product features

2.have good mechanical properties, temperature characteristic

3.fine steel wire armored garden more strengthen tensile and compressive properties of optical fiber cable

4.pine casing material itself has good hydrolysis resistance and high strength

5.Tube filled with special ointment, has carried on the key protection to optical fiber

6. good compressive resistance and softness

7. adopt the following measures to ensure that the cable waterproof performance:

8.To strengthen the core, a single metal center

9.slip-on filling special waterproof tube compound

10.core filled completely

11.Aluminum, plastic coated with moisture proof layer (APL)

12.good waterproofing fiber longitudinal block water materials

Technical parameters of fiber optic cable

|

project |

unit |

4B1 parameter |

96B1 parameter |

|

|

PRODUCT SIZE |

mm |

17.5±0.3 |

21.0±0.3 |

|

|

product weight |

Kg/Km |

520±10 |

600±10 |

|

|

drawing force |

long-term basis |

N |

10000 |

10000 |

|

short period |

N |

20000 |

20000 |

|

|

The force that press a flat |

long-term basis |

N/100mm |

1500 |

1500 |

|

short period |

N/100mm |

4000 |

4000 |

|

|

bending radius |

static state |

mm |

30D |

30D |

|

dynamic condition |

mm |

20D |

20D |

|

Optical fiber technology parameters

|

mode field diameter (um):8.8~9.5 |

The cladding diameter (um):125.0±1.0 |

|

The package layer out of roundness (%):<1 |

The core of concentricity error (um):≤0.6 |

|

Diameter of coating layer (um):245±10 |

Attenuation inhomogeneity (dB):≤0.05 |

|

Packages/coating concentricity error (um):≤12.0 |

Cutoff wavelength (nm):≤1260 |

|

Group of refractive index |

1310nm:1.4660 |

|

1550nm:1.4667 |

|

|

The dispersion (ps/nm.km) |

≤3.5(1288~1339nm) |

|

≤18(1550nm) |

|

|

Attenuation loss (dB/km) |

≤0.35(1310nm) |

|

≤0.22(1550nm) |

Laying way:Directly buried, underwater;

applicable temperature:-40℃~+60℃。